In the context of rapid digital transformation, many logistics companies are adopting the smart warehouse model to optimize their operations.

From automated robots and monitoring sensors to real-time data analytics, smart warehouses are gradually becoming the new standard in modern supply chains. So, what exactly is a smart warehouse, and how is it transforming the industry?

The following article by KTG Industrial provides a detailed analysis of this model and the practical value it brings to businesses.

What defines a smart warehouse?

A smart warehouse is a modern warehouse management approach that operates on a foundation of digital technology and automated systems to improve operational efficiency.

Going beyond traditional storage functions, this model integrates multiple advanced technologies such as sensors, artificial intelligence, and big data analytics to create a warehouse system that is flexible, precise, and optimized.

Instead of relying on manual operations, processes such as order receiving, product location tracking, and inventory checks are fully automated, helping reduce processing time and increasing operational reliability. Additionally, with the ability to automatically identify, categorize, and organize goods, the system enables a smooth and efficient flow of goods within the warehouse, minimizing the need for human intervention.

The adoption of modern technologies not only reduces unnecessary staff movement but also helps minimize errors in the workflow. As a result, productivity is significantly improved, while businesses gain tighter control over the quality and flow of goods across the entire system.

Smart warehouses are being increasingly adopted across various industries

Top smart warehouse technologies

Modern warehouse management system (WMS)

The modern warehouse management system (WMS) is one of the core technologies in the smart warehouse model and is widely implemented by logistics companies and warehouse rental providers. Acting as the “brain” of the warehouse, WMS oversees all operational activities in real time.

By continuously collecting data and generating visual reports, the system not only helps managers monitor work progress with precision but also analyzes trends to forecast risks and suggest timely solutions. This ensures warehouse operations stay on schedule, reduces errors, and enhances resource utilization efficiency.

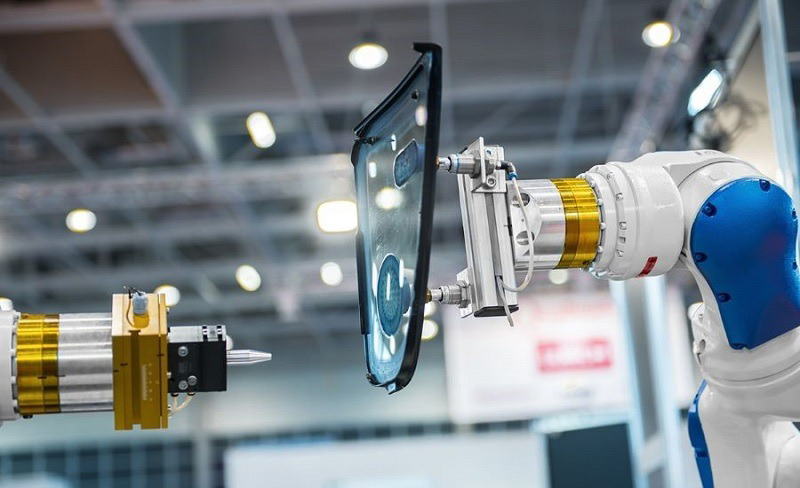

Smart automated picking technology

One of the standout technologies in smart warehouses is the automated picking system, which utilizes robots, sensors, and optimized pathfinding algorithms to improve order picking efficiency.

With the ability to accurately locate products and execute picking operations automatically, the system enables a faster and more accurate order fulfillment process.

Implementing this technology not only shortens order processing times but also minimizes errors during the picking stage and reduces pressure on operational staff. It is particularly ideal for businesses operating in e-commerce or retail sectors.

Automated picking helps businesses save on labor costs

AGV vehicles enhance operational performance

Automated guided vehicles (AGVs) play a crucial role in improving operational efficiency in smart warehouse models, thanks to their ability to transport goods autonomously without human control.

Equipped with advanced navigation systems, AGVs can move precisely along predefined routes within the facility.

There is a wide range of AGV types, including tow tractors, load carriers, under-run AGVs, forklifts, and those integrated with robots and autonomous mobile robots (AMRs), offering flexible solutions for various operational scenarios.

Integrating AGVs into a smart warehouse not only optimizes workflows but also helps reduce risks and labor costs.

Automated storage and retrieval system (AS/RS)

In addition to AGVs, the automated storage and retrieval system (AS/RS) is another key component in the smart warehouse model. By automating the entire storage and retrieval process, AS/RS helps save warehouse space and shortens order processing times.

Typically, AS/RS consists of high-rise racking systems paired with cranes or robots that move vertically and horizontally to quickly access goods. As a result, AS/RS not only enhances warehouse performance but also ensures operational accuracy and safety.

Application of the Internet of Things (IoT) in warehousing

No longer a futuristic concept, the Internet of Things (IoT) is now clearly present in every corner of smart warehouses. Through a network of sensors and connected devices, the system can “see” and respond in real time to changes occurring in the warehouse.

From tracking item locations and monitoring environmental conditions to evaluating equipment performance, all data is collected and analyzed to optimize operations. This connectivity has elevated warehouse logistics to a new level, more precise, more agile, and significantly more efficient.

Integrating artificial intelligence (AI) into warehouse management

Artificial intelligence (AI) is being increasingly embedded into warehouse management processes to boost accuracy and automation. AI helps analyze operational data, forecast demand, and provide timely adjustments in inventory allocation and goods movement.

Moreover, the system can detect anomalies and automatically issue alerts, minimizing operational risks.

AI enables warehouse processes to become more proactive, adaptive, and responsive to market changes

Mobile devices enable faster and more accurate operations

Mobile devices contribute significantly to accelerating task execution. With integrated functions such as barcode scanning, information lookup, and direct data entry, handheld tools like industrial smartphones or mobile scanners allow staff to operate flexibly right at the worksite.

Tasks such as stock checking, inbound/outbound confirmation, and system updates are performed instantly, minimizing delays and reducing errors.

Smart identification and inventory management using RFID technology

With RFID technology, manual barcode scanning is replaced by the ability to simultaneously identify multiple items, even without direct line-of-sight to the labels.

This makes inventory processes faster, more accurate, and less dependent on manual labor. Moreover, RFID enables real-time tracking of product location and status, enhancing visibility and control throughout the supply chain.

Big data integration in warehouse analytics

In smart warehouse models, big data is applied to forecast inventory trends, market demand, optimize transportation routes, analyze personnel and equipment performance, and provide early warnings of operational risks.

As a result, businesses can make strategic decisions based on actual data rather than intuition, improving management effectiveness and overall competitiveness.

Collaborative robots (cobots) for flexible operations

Cobots are robots designed to safely work alongside humans in shared spaces. In smart warehouses, cobots are often used to support tasks such as packaging, labeling, and material handling in hard-to-reach areas.

They work in coordination with sensors to perform precise operations in complex environments. This is an ideal solution for companies not yet ready for full automation but still aiming to improve efficiency and maintain operational safety.

Surveillance cameras enhance security and quality control

In smart warehouses, surveillance systems monitor staff and equipment activities in real time, detect irregularities early, and document operational processes. This allows businesses to ensure safety, facilitate traceability, and improve transparency in warehouse management.

Application of barcodes and QR codes in traceability and inventory management

Using barcodes and QR codes in smart warehouses automates processes such as locating goods, speeding up inbound and outbound procedures, accurate inventory counts, and real-time stock updates via the WMS. This helps businesses save time, reduce errors, and optimize operational costs.

Applications of the smart warehouse model

An increasing number of large enterprises are adopting the smart warehouse model as a strategic solution to enhance their competitive edge in the market. In sectors such as pharmaceuticals, food, and cold chain storage, advanced technologies are implemented to ensure safe and accurate operations.

Additionally, transit and distribution warehouses are being equipped with modern systems to optimize space utilization and reduce manual labor.

Core technologies like automation, artificial intelligence (AI), the Internet of Things (IoT), and RFID are deeply integrated into warehouse processes, improving inventory control and shortening order processing times.

With these smart operational systems, businesses not only boost operational efficiency but also realize tangible profit gains.

Are smart warehouses expensive? A practical cost analysis

Smart warehouses typically require a relatively high initial investment due to the need for advanced systems such as AGVs, AS/RS, IoT, AI, RFID, and warehouse management software (WMS).

However, when analyzed from a long-term perspective, this model proves to be economically advantageous thanks to reduced labor costs, space savings, inventory optimization, and minimized operational errors.

Moreover, businesses can implement smart solutions in phases to better manage budgets, rather than committing to a full-scale investment upfront. Many technology providers now offer customizable packages tailored to different scales and operational needs, giving businesses greater flexibility in deployment.

A smart warehouse is a worthwhile investment for sustainable, long-term growth

Advantages and disadvantages of the smart warehouse model

Advantages of the smart warehouse model

The advantages of this model go beyond the adoption of modern technologies—they are reflected in the tangible benefits it delivers to businesses during both operational and management processes. Key benefits include:

- Enhanced operational efficiency: Automation streamlines workflows, reduces order processing time, and improves inbound-outbound-inventory handling speed.

- Labor cost savings: Minimizes reliance on manual labor, especially in repetitive tasks such as inventory counting and internal transport.

- Accurate inventory management: With the integration of AI, IoT, and RFID, product data is updated in real time, minimizing losses and discrepancies.

- Optimized storage space: Automated storage systems make full use of vertical and horizontal space, lowering facility costs.

- Improved scalability and adaptability: The model is flexible and can be expanded or adjusted to fit the size and growth needs of the business.

- Increased safety: Sensors and surveillance systems detect potential issues early, ensuring safety for both goods and personnel.

- Faster, more informed decision-making: Clearly presented analytics and real-time data empower managers to develop effective strategies.

Disadvantages of the smart warehouse model

Despite its many strengths, the smart warehouse model also has certain limitations that businesses should carefully consider before making an investment. These include:

- High initial investment: Implementing automation systems and modern management software requires a significant upfront budget.

- Infrastructure requirements: Warehouses must be designed or retrofitted to meet new technology standards.

- Extended implementation time: System integration and employee training can be time-consuming and resource-intensive.

- Technology risks: Software bugs or technical issues can disrupt operations.

- High technical expertise: Staff must possess in-depth knowledge to operate, monitor, and troubleshoot the system.

- Ongoing operational and maintenance costs: Advanced technologies require regular maintenance and periodic upgrades.

That said, when properly invested in and implemented, these disadvantages can be effectively managed and outweighed by long-term benefits

How do smart warehouses differ from traditional warehouses?

Amid the ongoing digital transformation, many businesses have begun transitioning from traditional warehouses to smart warehouse models to improve operational efficiency.

The differences between the two models go beyond the level of technology adoption—they are clearly reflected in workflows, costs, performance, and management capabilities.

Below is a comparison of key differences between smart and traditional warehouses:

| Comparison | Smart warehouse | Traditional warehouse |

| Operational processes | Fully automated and digitized across all stages: inbound, outbound, and storage | Manual execution, heavily dependent on human labor and paperwork |

| Automation level | Integrated systems such as AGV, AS/RS, RFID, IoT, and WMS | Little to no technology application |

| Operational efficiency | Fast, accurate, fewer errors, higher order processing speed | Slow processing, error-prone, hard to scale as volume increases |

| Operating costs | High upfront investment, but long-term savings through labor and space efficiency | Lower initial costs but higher long-term expenses due to labor dependency |

| Management capabilities | Real-time monitoring, accurate inventory control, faster decision-making | Disconnected management, limited data, difficult to forecast |

| Benefits | Cost optimization, improved productivity, stronger competitive advantage | Easier to deploy at small scale, but less efficient in the long run |

Is a hybrid approach between traditional and smart warehouses feasible?

It is entirely feasible to combine both models to create a flexible solution tailored to each stage of business development.

For example, companies can maintain traditional warehouse areas to handle low-value or non-urgent goods, while investing in smart warehouse zones for high-precision, high-speed operations such as packaging, sorting, or storing products with short life cycles.

Moreover, individual technologies such as a warehouse management system (WMS) or mobile scanners can be integrated into traditional warehouses as a gradual step toward modernization, without requiring a complete infrastructure overhaul.

Therefore, businesses do not need to choose exclusively between one model or the other. A hybrid approach offers the flexibility to optimize both operational efficiency and capital investment.

6 steps to establishing a smart warehouse model

Establishing a smart warehouse requires a structured roadmap to ensure operational consistency and effectiveness. Below are six fundamental steps to help businesses transition from a traditional warehouse to a smart warehouse model:

- Step 1 – Assess current operations: Analyze the existing warehouse system to identify weaknesses and improvement needs.

- Step 2 – Define objectives: Clarify the goals of the transformation—such as increasing processing speed, optimizing space, or reducing costs.

- Step 3 – Select technologies: Choose appropriate solutions based on budget and priorities, such as WMS, AGVs, RFID, IoT, etc.

- Step 4 – Redesign warehouse layout: Rearrange the warehouse layout to integrate new equipment and optimize workflow.

- Step 5 – Implement and train: Install the systems and provide training to staff on how to use the new technologies effectively.

- Step 6 – Monitor and optimize: Continuously track performance, assess outcomes, and make adjustments for ongoing improvement.

Following this structured process helps minimize risks during the transition and lays a strong foundation for a modern, flexible logistics system.

Conclusion

The smart warehouse model is not just a digital trend, it is a strategic solution that enhances operational efficiency, reduces errors, and optimizes costs.

The adoption of advanced technology in warehousing is no longer a distant concept, but an increasingly practical and accessible path for many types of businesses.

Whether implemented all at once or in phases, the smart warehouse serves as a vital foundation for building a flexible, accurate, and sustainable supply chain for the future.