In an industrial facility, ensuring a cool and well-ventilated workspace is crucial, alongside maintaining hygiene and safety. High temperatures and inadequate ventilation not only impact employee health but also reduce work efficiency and product quality. Currently, the market offers various cooling and ventilation solutions, with louvers being a noteworthy option. Join KTG Industrial as we explore the characteristics of louvers to help businesses make informed decisions when selecting a suitable factory.

What are Industrial Louvers?

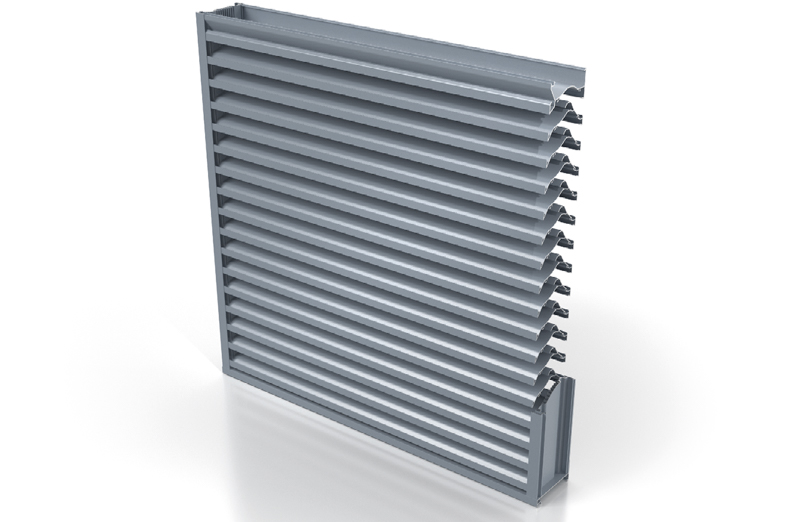

Industrial louvers, also known as industrial shutters, consist of strategically angled blades forming a robust framework. This design allows industrial louvers to effectively draw in natural wind, enhancing ventilation within enclosed spaces while also serving as a protective barrier against external elements. This protective layer helps mitigate negative external environmental impacts such as driving rain, harsh direct sunlight, and insect intrusion.

Industrial louvers are a smart and versatile solution for industrial facilities.

Structure of Industrial Louvers

A complete industrial louver system comprises two primary components:

- Louver Blades: Horizontally arranged slats typically made of metal, designed at specific angles. This design creates openings that allow for selective circulation of wind and light.

- Steel Frame: The steel frame serves as the main load-bearing component of the entire system. It is typically constructed from steel alloys, galvanized steel, or aluminum. These materials are chosen for their rigidity and formability, which help protect the inner louver blades and ensure the structural stability of the installation.

Essentially, the structure of industrial louvers is quite simple yet ensures effective ventilation and protection.

What are the Functions of Industrial Louvers?

Industrial louvers serve several critical functions, contributing to an efficient and comfortable working environment.

One of their primary functions is regulating air circulation. They enhance natural ventilation, ensuring fresh air constantly circulates within the facility, leading to a healthier atmosphere. Additionally, the adjustable blade angles enable precise control of airflow, optimizing the overall ventilation system’s performance.

Moreover, industrial louvers can control natural light. The angle of the louver blades can be adjusted to manage the amount of light entering, reducing harsh glare and creating a more pleasant workspace. Utilizing natural light also helps businesses significantly reduce electricity costs for lighting.

Furthermore, industrial louvers play a crucial role in protection from external environmental factors. They effectively prevent rainwater and dust from entering the facility, keeping the factory space clean. In some cases, louvers can also be equipped with mesh screens to prevent insect intrusion.

Beyond their functional benefits, louvers also enhance the aesthetic appeal of the building. With a variety of designs, colors, and materials available, louvers can be customized to complement the overall architectural style of the factory, lending a more modern and professional appearance.

Operating Principles of Louvers

One of the core principles behind industrial louvers is natural ventilation. When there’s a pressure differential between the inside and outside of the factory, air automatically moves through the gaps between the louver blades. Warm air inside, which tends to rise, escapes through the louvers, simultaneously drawing in cooler outside air. This creates a natural airflow that cools the space without consuming energy.

Additionally, industrial louvers operate on the principle of light regulation. By adjusting the angle of the louver blades, users can control the amount of natural light entering the interior. This not only helps create a workspace with appropriate lighting and reduced glare but also contributes to significant energy savings on artificial lighting systems.

Furthermore, the special design of the louver blades allows them to function as a barrier against wind and rain. The blades are shaped and angled to prevent rainwater from directly splashing inside. Simultaneously, they help mitigate the impact of strong winds on other surfaces of the factory, protecting the building’s structure and extending its lifespan.

Industrial louvers operate based on simple yet effective physical principles, aiming to optimize air circulation and control internal environmental factors.

Classification of Louvers

| Category | Type of Louver | Characteristics |

| By Function | Ventilation Louver | Designed to optimize airflow, expelling stale air and drawing fresh air into the factory. |

| Rain Louver | Features a special structure to prevent rainwater intrusion, keeping the factory interior dry. | |

| By Installation Location | Wall Louver | Installed on exterior or interior walls to support cross-ventilation and facilitate airflow. |

| Door Louver | Integrated into factory doors, ensuring ventilation even when the door is closed, while also allowing for controlled visibility and enhanced privacy. | |

| By Material | Aluminum/Steel/Stainless Steel Louver | Manufactured from metallic materials such as aluminum, steel, or stainless steel, offering high durability and excellent corrosion resistance, making them suitable for industrial environments. |

Outstanding Characteristics of Louvers

Industrial louvers possess several notable characteristics that provide significant advantages in ventilating and protecting industrial facilities.

- Smart Louver Structure: Featuring horizontal or vertical designs with evenly spaced openings, this structure optimizes natural air circulation, ensuring a consistently airy interior and minimizing stuffiness.

- Durable Materials, Long Lifespan: Common material choices include aluminum, galvanized steel, or engineering plastics. These materials offer corrosion resistance and oxidation prevention, ensuring a long operational life for the system.

- Flexible Angle, Adjustable Capability: This allows users to easily control the direction of airflow and the amount of natural light entering the factory, creating a comfortable working environment tailored to specific needs.

- Flexible Installation, Wide Application: The design of industrial louvers is suitable for various installation locations, from perimeter walls to factory roofs. This allows for their broad application across numerous types of industrial buildings.

- Effective Waterproofing Capability: This advantage helps keep the interior space dry and clean, which is particularly crucial for industries with high demands on their working environment.

Industrial louvers boast numerous outstanding characteristics, creating many advantages in ventilating and protecting industrial facilities.

Guidelines for Selecting Industrial Louvers

Important Considerations When Choosing Louvers for Your Factory

To select the most suitable and effective industrial louvers, businesses need to carefully consider several key factors:

- Determine Ventilation Needs: First, clearly define the required airflow for the factory. This depends on the area, number of employees, type of production, and other heat-generating factors. If there’s a high demand for ventilation, consider installing more louvers, choosing types with wider opening angles, or larger sizes.

- Evaluate Factory Area and Layout: The scale and layout of the factory space will influence the selection and arrangement of louvers. It’s essential to ensure harmony between the number and size of louvers and the overall architecture, achieving both optimal ventilation effectiveness and aesthetic appeal. Avoid installing too many large louvers in a small space, which can lead to waste and an imbalanced appearance.

For example, for a moderately sized factory, choosing two medium-sized louvers might be sufficient to meet ventilation needs while ensuring aesthetic appeal and optimizing installation and operational costs.

How to Calculate the Number of Louvers Needed for a Factory

The formula for calculating the number of louvers to install in a factory is as follows:

Step 1: Calculate the required airflow for the factory space: Tg=V×X

Where:

- Tg: Required airflow (m3/hour).

- V: Volume of the factory (m3).

- X: Air changes per hour (ACH) – the number of times the air in the space is completely replaced in one hour.

Step 2: Calculate the number of louvers to install: N=Tg/Q

Where:

- N: Number of louvers to install (units).

- Tg: Required airflow (m3/hour).

- Q: Airflow capacity of a single louver (m3/hour).

Through the information just shared, KTG Industrial hopes that readers have gained a comprehensive overview of the structure and operating principles of louvers – an effective ventilation solution for factories.