The electrical system in a factory operates like the “backbone” that powers the entire production line—but even a small error can lead to far-reaching, unpredictable consequences. That’s why strict compliance with electrical safety regulations is a fundamental requirement for businesses to ensure workplace safety and maintain stable operations. In this article, KTG Industrial outlines core regulatory requirements and practical safety measures to help minimize electrical risks in factory settings.

3 essential electrical safety regulations in factories: What businesses and workers must follow

Electrical safety for factory workers and staff

Electrical safety is one of the top priorities in any factory environment, playing a critical role in protecting lives and minimizing risks to property. To ensure a safe working environment, workers and staff must strictly adhere to the following key regulations:

- Operate electrical equipment only when authorized: Employees and workers are only permitted to handle electrical devices such as circuit breakers, switches, or start buttons if it falls within their assigned responsibilities. Equipment like compressors, pumps, or industrial fans must be used with particular caution. Unauthorized access or tampering with electrical systems is strictly prohibited.

- Disconnect power after use: When electrical equipment is no longer required for the task at hand, workers must fully disconnect the power supply. This habit plays a vital role in preventing accidents and ensuring a safe working environment.

- Do not restore a tripped circuit without approval: If a circuit is interrupted by protective devices such as a circuit breaker or fuse, it must not be switched back on without proper inspection and approval from a qualified electrical technician. This ensures safety before the system is reactivated.

- Respond immediately to abnormal signs: If any unusual signs are observed—such as smoke, burning smells, or abnormal noises—employees must promptly report the issue to the person in charge. Immediate shutdown of the equipment may be required to prevent potential accidents.

- Avoid unauthorized access or interference with electrical systems: Workers must not enter areas containing live electrical equipment or wiring unless assigned to do so. Unauthorized repair, modification, or connection of any part of the electrical system is strictly prohibited without proper expertise or formal assignment.

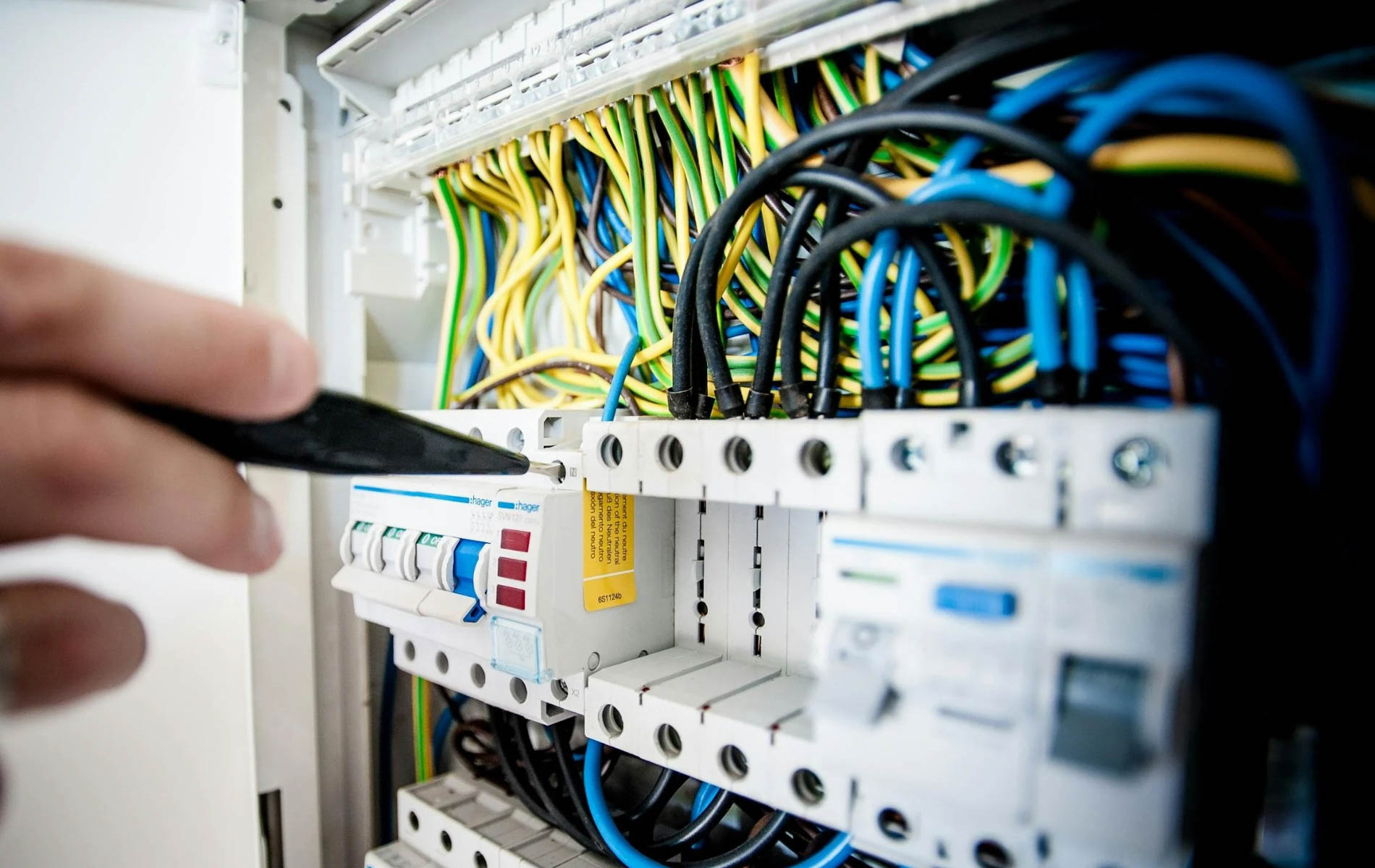

All factory workers and staff must clearly understand electrical safety regulations to minimize risks to life to the greatest extent possible

Electrical safety for business owners and factory operators

In addition to ensuring that workers and staff strictly follow electrical safety regulations, business owners and factory operators play a crucial role in creating a safe working environment. Below are key requirements that factory leaders should keep in mind:

- Hire qualified personnel for electrical work: All activities related to the installation, maintenance, repair, or upgrade of electrical systems must be performed by trained professionals. Factory owners should only employ certified electrical technicians who have undergone formal training in electrical safety to ensure that all work is carried out according to technical standards.

- Install warning signs in hazardous areas: In locations where high-voltage equipment is present or there is a risk of electrical accidents, clearly visible and attention-grabbing warning signs must be installed. These serve to remind workers to stay alert and keep a safe distance from dangerous zones.

- Conduct regular grounding resistance measurements: Businesses must schedule grounding resistance checks for electrical equipment at least twice a year. If measurements exceed 2Ω, corrective measures must be taken promptly to bring the system back within the safety threshold as required by regulations.

- Do not install electrical equipment in high-risk areas: Electrical devices must not be installed in locations with high humidity, water exposure, or unstable surfaces—such as slippery floors or structurally weak areas. This measure helps prevent short circuits, fire hazards, and accidents during operation.

Electrical safety for industrial electrical technicians

As the personnel directly handling the electrical system, industrial electrical technicians play a vital role in ensuring the safe operation of equipment. Therefore, strict adherence to the following safety principles is mandatory to prevent incidents and protect lives:

- Disconnect power and ground equipment before working: Before performing any repair or maintenance, technicians must ensure the equipment is fully disconnected from the power source and properly grounded. This eliminates the risk of electric shock or leakage incidents.

- Follow correct electrical procedures with supervisory coordination: All actions involving switching electrical equipment on or off must strictly follow the pre-established work procedure outlined in the operation sheet. At least two people must be present to supervise and coordinate the process, minimizing risk and preventing mistakes.

- Isolate power and post warning signs during maintenance: During maintenance, two technicians must work together to complete the electrical isolation process. A clear “Do Not Energize” warning sign must be displayed on the main switch for the entire duration of the task.

- Adhere to procedures and post-maintenance protocols: Technicians must follow all steps as specified in the work permit and technical procedures. Upon completion, equipment must be inspected, accepted, the permit returned, and relevant personnel notified so the system can be safely returned to normal operation.

- Use only low-voltage portable lights for localized illumination: For temporary lighting during repairs, only handheld lamps with a maximum voltage of 36V should be used to ensure safety and prevent electric shock risks.

- Always wear safety harnesses when working at heights: When working in elevated areas, technicians must use certified safety harnesses to prevent accidents caused by slips, falls, or loss of balance.

- Warning signs or lockout devices must be placed at power isolation points: When disconnecting power at circuit breakers, switches, or connection points, clear warning signs or lockout devices must be installed to prevent accidental re-energizing during work.

- Wear proper protective gear in high-risk electrical zones: Before entering areas with live electrical equipment or potential electrical hazards, technicians must wear dry clothing, insulated footwear, and certified safety helmets.

- Remove metal personal items and use full insulation equipment: When working on live equipment, all metal jewelry and accessories must be removed, and proper insulating gloves, boots, and tools complying with technical standards must be used.

- Do not use conductive ladders near live electrical areas: Avoid using ladders made of metal or other conductive materials when working at or near electrical equipment to maximize safety.

Strict compliance with electrical safety regulations in factories helps technicians avoid risks and ensures stable operation of electrical systems

Electrical safety regulations in production under Vietnam’s Electricity Law

In the industrial production environment, ensuring electrical safety is not only a technical requirement but also a mandatory regulation explicitly stated in Article 57 of the Electricity Law 2004 (amended in 2012). Businesses, organizations, and individuals using electricity for production purposes must comply with the following principles:

- All electrical activities must comply with the electrical safety standards and technical regulations issued by Vietnam to minimize the risk of incidents and ensure occupational safety.

- All electrical systems and equipment, including grounding and lightning protection systems, must undergo initial certification, periodic inspections, or ad-hoc checks as required by technical standards. System diagrams must accurately reflect the actual installation and be stored along with inspection reports throughout the system’s operational lifespan.

- The installation and operation of substations, high-voltage electrical equipment, and internal high-voltage lines must strictly adhere to relevant technical safety regulations.

- Electrical equipment within the system must conform to standards such as “Low-voltage electrical equipment – General requirements for protection against electric shock” and “Regulations on grounding and neutral connections of electrical equipment” to prevent electric shock accidents.

- Electrical wiring and cables must be designed and installed to maintain clear factory floor space and avoid exposure to damaging factors such as mechanical impact or corrosive chemicals. Additionally, metallic structural components within the factory (such as steel frames, metal conduits, etc.) must not be used as neutral conductors unless specifically designed and approved by the authorized agency.

- In production areas with high fire and explosion risks, electrical systems must be designed, installed, and operated in accordance with Clause 4, Article 54 of the Electricity Law.

- Electrical equipment used in mining operations, mobile equipment, welding machines, electrolysis, electroplating, and similar activities must meet the respective specialized safety standards and regulations to ensure stable and safe operation.

Related article: Current electrical codes for industrial facilities in Vietnam

Measures to reduce electrical accidents in factories

Self-protection measures

To minimize the risk of electrical accidents in production areas, workers must proactively adopt personal safety measures, especially when working near or directly interacting with electrical equipment. It is essential for workers to be fully equipped with safety tools such as insulating poles (for remotely operating circuit breakers), insulated pliers, voltage testers, insulating gloves and boots, and insulating rubber mats.

In addition, personal protective equipment (PPE) like safety goggles, fabric protective gloves, face masks, and safety harnesses must be properly used, particularly when working in high-risk zones for electric shock or at heights. A crucial note is to only use tools and equipment that have been quality certified and are rated within specified voltage limits. Regular inspections of protective tools are necessary to promptly detect any damage or wear.

Finally, protective tools should be stored in dry, clean areas, avoiding exposure to chemicals like gasoline or oil and being kept away from zones prone to mechanical impacts that could damage the insulating layers.

Techniques to ensure electrical safety in factories

First, areas prone to collisions or with exposed equipment must be protected by insulating layers to prevent unwanted electric shock incidents. Additionally, electrical devices should be inspected annually using an MW meter to ensure the insulation layer meets standards, with a resistance index exceeding 1 kΩ/1V.

Alongside that, grounding of devices and machine casings is extremely important to ensure electrical safety and minimize the risk of electric shock accidents. High-voltage areas must be equipped with barriers and clear warning signs such as “no switching on” or “danger” to alert workers to keep away.

Maintaining a safe distance between electrical equipment and workers is another indispensable factor. This distance varies depending on voltage levels, for example: for 2–15 kV, the distance is 0.7 m; for 15–35 kV, it is 1.1 m; and for 330–500 kV, it is 4 m, ensuring safety for personnel.

The electrical system must also have an automatic shut-off mechanism in case of leakage current to promptly protect workers. Finally, for tasks requiring electricity use, choosing low voltage (such as 36V lighting) is necessary to reduce the risk of electric shock accidents.

Minimizing electrical accidents in factories requires the strict and effective implementation of technical measures

How to handle industrial electrical accidents

When an electrical accident occurs in an industrial setting, even if all safety measures have been followed, timely and proper handling can determine the victim’s survival. Here are the immediate steps to take when an electric shock incident happens:

- First, cut off the power source at the accident site. This is the most crucial step to immediately stop the electric current and prevent the victim from continuing to be shocked. For high-voltage equipment, anyone present must switch off the circuit breaker before proceeding with the next steps.

- Next, separate the victim from the power source. Since the strong electric current may prevent the victim from removing themselves, those nearby should use safety equipment such as insulating gloves, insulating rods, or insulating boots to safely detach the victim from the electrical source.

- After separating the victim from the electricity, first aid must be provided immediately. The faster and more accurately it is done, the higher the chances of saving the victim’s life. The rescuer should place the victim in a well-ventilated area, loosen their clothing, and elevate their head. Keep the victim warm, and if they stop breathing or their heart stops beating, perform artificial respiration and chest compressions.

- If after first aid the victim’s condition remains unstable or there are no signs of life, those present must take the victim to the nearest medical facility for timely treatment.

Electrical safety tools and protective equipment

When working with electrical systems, using personal protective equipment is extremely important. These tools help prevent electrical accidents and protect workers from the risk of electric shock during work. Below are some commonly used electrical safety devices in the industry:

- Insulating mats: Used to protect workers from electric shock when in contact with high-voltage electrical equipment.

- Insulating gloves: Protect hands from electric shock when working near electrical devices.

- Insulating shoes: Help protect the feet when working on the ground or in areas with electricity.

- Insulating boots: Used in environments with a high risk of electric shock to protect the feet from current.

- Insulating rods: Tools used to operate circuit breakers or switches from a safe distance.

- Portable grounding devices: Equipment that provides temporary grounding when performing electrical tasks.

- Insulating helmets: Protect the head from electric shock hazards, especially when working in high-voltage areas.

Using the appropriate protective equipment is a crucial factor in minimizing risks when working with electricity

Benefits of ensuring electrical safety in industrial facilities

Ensuring electrical safety in industrial facilities not only protects workers from the risks of electric shock accidents but also helps safeguard the environment and the company’s assets. When safety procedures are properly followed, electrical equipment operates reliably, minimizing the risk of damage and fire, thereby protecting both property and human resources.

Moreover, a safe working environment enhances labor productivity, as workers feel more secure and can focus better on their tasks. This not only improves work quality but also reduces downtime caused by electrical incidents, thereby boosting overall production efficiency.

Compliance with electrical safety regulations also helps businesses reduce legal risks and avoid penalties related to violations of occupational safety laws. At the same time, maintaining a safe work environment enhances the company’s reputation in the eyes of customers and partners, contributing to building a trustworthy brand.

Conclusion

Thus, complying with electrical safety regulations in industrial facilities is not only a mandatory requirement to minimize risks and protect the health of workers and company assets but also a strategic approach to building a safe and efficient working environment. By fully implementing safety measures, organizations can enhance labor productivity and safeguard their corporate reputation. Prioritizing electrical safety serves as a solid foundation for sustainable growth in manufacturing operations.