Since the 1950s, the 5S system in factory management has been a “secret weapon” to enhance production efficiency. This method quickly spread across modern factories worldwide. In this article, KTG Industrial will share how to apply the 5S system to optimize factory performance, thereby delivering sustainable value for businesses.

Overview of the 5S system in factory management

The 5S system in factory management originated in Japan and was developed in the 1950s as part of the Toyota Production System (TPS). The goal of 5S is to create an organized, clean, and efficient working environment, thereby increasing productivity and reducing waste in the production process.

Initially, this method was applied at Toyota’s manufacturing plants to optimize the workspace. Later, due to its significant impact on increasing productivity and reducing waste, 5S quickly spread to various industries and countries worldwide and became an integral part of modern quality management systems.

Today, 5S is not only limited to the manufacturing sector but is also widely applied in services, healthcare, education, and many organizations globally.

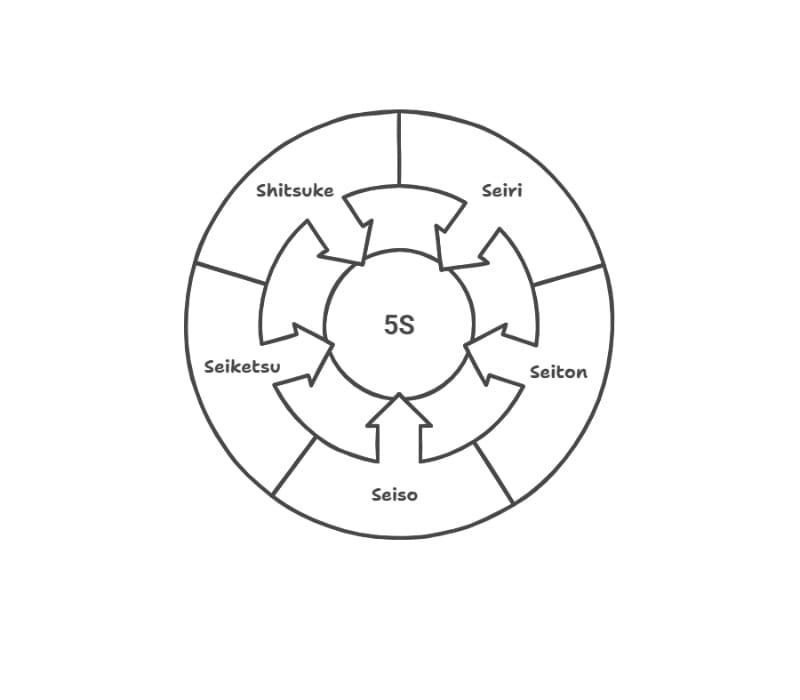

“5S” is an acronym for five Japanese terms that begin with the letter “S”

What does the 5S process include?

The 5S process consists of five steps, corresponding to five Japanese terms, with each step playing an essential role in building and maintaining an efficient working environment:

- Step 1 – Seiri (Sort): This stage focuses on removing unnecessary items from the workspace, keeping only those that are truly useful. The goal is to optimize space and minimize waste.

- Step 2 – Seiton (Set in Order): After sorting, the remaining items are arranged logically to be easy to find, use, and return to their proper place after use. This helps reduce handling time and improves work efficiency.

- Step 3 – Seiso (Shine): Regular cleaning of the workplace is carried out to ensure the space remains clean, while also helping to identify any faults or abnormalities in equipment and machinery early on.

- Step 4 – Seiketsu (Standardize): This step aims to maintain the results achieved in the previous three steps by establishing standardized procedures, issuing specific guidelines, and assigning responsibilities for each area.

- Step 5 – Shitsuke (Sustain): Focuses on building a culture of discipline and responsibility in adhering to 5S, forming good habits as a part of the company culture.

Core principles in the 5S system

To effectively implement the 5S system in factory management and maintain it over the long term, it is essential to fully adhere to the five steps of Seiri – Seiton – Seiso – Seiketsu – Shitsuke. However, this alone is not sufficient. Companies must pay particular attention to the following seven critical factors:

- Principle 1 – Establish standard work: This is the foundation for stabilizing production, which includes three elements: production rhythm based on customer demand (takt time), sequence of operations, and standard inventory levels. When work is standardized, the flow of materials becomes easier to control, processes stabilize, and waste is minimized.

- Principle 2 – Optimize layout for logistics: This principle ensures that the flow of raw materials and finished products is continuous and uninterrupted. Standards for pace, quantity, and specifications in logistics activities contribute to creating a tidy and organized working environment.

- Principle 3 – Perform autonomous maintenance: Employees directly participate in cleaning and inspecting equipment, ensuring the Seiso (Shine) step is followed while also helping to detect any operational abnormalities early. Such proactive maintenance not only extends the life of machinery but also contributes to maintaining a clean and safe working environment.

- Principle 4 – Effective management of defective goods: Implementing a scientific defect control system, with clearly classified and easily visible sorting trays, helps address defective products promptly and prevents them from affecting overall quality. This requires strict adherence to identification, positioning, and quantification rules while enhancing the reliability and efficiency of the production line.

- Principle 5 – Data control: In modern manufacturing, data is no longer a secondary factor but a core tool for decision-making. Proper, timely, and transparent recording, along with the standardization of forms and collection tools, greatly supports the organization, visualization, and retrieval of information.

- Principle 6 – Encourage a culture of continuous improvement: Under the Seiketsu (Standardize) principle, adjusting standards in steps S1, S2, and S3 to align with practical realities is necessary. However, each improvement must be accompanied by updating the standards to ensure consistency and avoid disruptions in operations.

- Principle 7 – Empower the role of team leaders: As direct supervisors on the shop floor, team leaders act as the link between the management system and production reality. They not only monitor the application of the 5S principles but also have the ability to identify emerging issues and implement appropriate solutions.

Companies need to establish and maintain principles for a modern and sustainable production culture

5 specific steps for implementing 5S in the factory

Step 1: Develop a deployment plan and prepare necessary resources

The first step is to create a detailed plan and allocate appropriate resources. The management team should form a 5S task force with representatives from production, maintenance, logistics, and other relevant departments to ensure coordinated efforts across the entire plant.

At the same time, clear implementation goals should be set—these goals must be specific, feasible, and measurable to facilitate progress tracking and assess implementation effectiveness. The deployment plan should outline key timelines, personnel requirements, and individual responsibilities within the team.

Additionally, internal communication plays a crucial role in raising awareness among workers and factory staff. Organizing training sessions, providing visual guides, or displaying banners and bulletin boards in the production area will help effectively spread the 5S spirit.

Building a detailed plan and allocating resources is essential when starting

Step 2: Train staff on 5S thinking and methods

It is crucial to organize training sessions to ensure employees fully understand the basic concepts, goals, and steps of 5S. This will help them recognize the benefits and importance of this method in their daily tasks.

Additionally, inviting companies that have successfully implemented 5S to share practical experiences will provide valuable lessons and help employees realize the positive results this method can bring. To ensure the effective implementation of 5S, businesses should provide comprehensive, easy-to-understand instructional materials, enabling employees to easily reference and apply them in their work.

Step 3: Implement 5S in specific functional areas

After completing the preparation and training, businesses need to implement the 5S system across different functional areas to ensure consistency and effectiveness. Starting with sorting—eliminating unnecessary items to create a tidy space—the next step is to arrange the remaining items in a systematic way that makes them easy to find and access.

Next, businesses should clean the work areas and equipment thoroughly, ensuring safety and making it easier to detect any damage. The “Sustain” step ensures that the results achieved are maintained and that the workplace remains organized. Finally, creating a habit of regularly performing 5S is foundational to building an efficient and sustainable work environment.

Step 4: Monitor, evaluate, and continuously improve the process

Companies need to establish clear evaluation criteria, such as using charts and checklists to measure the level of 5S implementation in different areas.

Regular evaluations, either weekly or monthly, will help quickly identify any issues or shortcomings in the process, enabling prompt corrective actions. Based on evaluation results, businesses should continuously improve and adjust the 5S process to achieve better efficiency in subsequent cycles.

Step 5: Maintain effectiveness and build a sustainable 5S culture

To ensure that 5S is not just a temporary method, businesses need to implement clear regulations regarding 5S practices, ensuring that all employees understand and strictly adhere to them.

Competitions and performance activities not only create a competitive atmosphere but also encourage employees to maintain and improve the process. At the same time, recognizing and rewarding individuals or teams with excellent performance will help reinforce responsibility and motivate everyone. These actions will contribute to building a sustainable 5S culture, promoting the long-term and continuous development of the process within the company.

The purpose of the 5S system

The implementation of the 5S system is not only aimed at improving the working environment but also contributes to the sustainable development of the business. By fostering a culture of continuous improvement across the entire workforce, the 5S program helps create a tidy, safe, and efficient work environment.

This encourages collaboration and teamwork while also promoting coordination between departments, allowing all employees to participate in the improvement process. Additionally, the 5S method supports the development of leadership skills among managers, providing opportunities for them to engage in practical activities and hone their management abilities.

Finally, 5S establishes a solid foundation for applying future improvement methods, thereby enhancing labor productivity, work quality, and the overall competitiveness of the business.

For sustainable development, the application of the 5S system in workshop management is essential

What are the benefits of implementing the 5S system in workshop management?

Benefits for businesses

Implementing the 5S system in workshop management creates a clean and organized working environment, thereby improving labor productivity and reducing waste in terms of time and costs. A scientifically organized workspace enables workers to easily find and use the necessary tools and equipment, improving work efficiency.

Moreover, maintaining the 5S process in the workshop not only helps minimize workplace accidents but also enhances the quality of products and services, which in turn improves the competitiveness and reputation of the workshop in the eyes of customers and partners.

Benefits for employees

In a workshop that applies the 5S system, employees will feel safer and more comfortable due to the always clean and organized workspace. This not only reduces stress but also fosters teamwork and collaboration among team members.

Additionally, participating in the process of maintaining 5S helps employees develop self-discipline, responsibility, and enhance their skills. All these factors contribute to improving the quality of life and job satisfaction for employees in the workshop.

Challenges in applying 5S in workshops in Vietnam: Common difficulties

Implementing the 5S system in workshop management in Vietnam faces several challenges.

One major issue is the awareness and commitment of employees. Due to the requirement for continuous participation from the entire workforce, many companies have not conducted adequate awareness campaigns or training, leading to a lack of motivation and commitment from employees. This is particularly common in large companies with a large workforce, where maintaining consistency in implementing 5S becomes a significant challenge.

In addition, the lack of resources to implement 5S systematically is another issue. Companies, especially small and medium-sized enterprises, often struggle with allocating budgets for training activities, improving infrastructure, and investing in tools that support 5S. As a result, the implementation process is often inefficient and lacks sustainability.

Furthermore, corporate culture and leadership support significantly impact the success of implementing 5S. In some cases, leadership does not prioritize the implementation of 5S or lacks clear guidance, causing employees to not fully understand the importance of this system.

Solutions to address these issues include enhancing training and communication for all employees about the benefits and importance of 5S, thereby raising awareness and commitment. At the same time, companies need to ensure they allocate sufficient resources for 5S implementation, particularly budgets for training and investment in necessary supporting tools. Furthermore, strong leadership support and clear direction will help drive the effective and sustainable adoption of 5S.

Overcoming these challenges will help optimize workshops and support business development in Vietnam

Integrating 5S into other management models

Combining 5S and Lean Manufacturing

Integrating 5S with Lean Manufacturing helps optimize production processes and reduce waste. 5S creates a tidy and well-organized working environment, forming the foundation for Lean Manufacturing.

When combined, 5S helps eliminate unnecessary items and organizes work effectively, supporting Lean Manufacturing in reducing waste such as waiting time and unnecessary movement. The improved working environment created by 5S also optimizes workflow, reduces the time spent searching for tools and materials, thereby increasing productivity and product quality.

Combining 5S with other management models aims to enhance the efficiency of workshop operations

Combining 5S and Kaizen

The integration of 5S and Kaizen provides a continuous improvement cycle, where each method supports and reinforces the other, creating an efficient and high-productivity work environment. 5S, through organizing and standardizing the work environment, serves as a solid foundation for continuous improvements in the spirit of Kaizen.

While 5S helps maintain a clean, tidy, and organized workspace, Kaizen drives the ongoing improvement process, ensuring sustainable progress over time. Additionally, this combination not only helps identify and address issues effectively but also fosters a culture of improvement within the organization, encouraging all employees to participate in initiatives that enhance work efficiency.

Integrating 5S into the ISO 9001 quality management system

Integrating 5S into the ISO 9001 quality management system offers several benefits in improving production processes and work quality. Firstly, 5S creates a clean, safe, and efficient working environment, which aligns with the environmental requirements of ISO 9001 (Clause 7.1.4). This not only increases productivity but also minimizes production incidents.

Moreover, 5S supports the standardization of work processes, optimizing steps and meeting the process management requirements in ISO 9001 (Clause 4.4). The scientific organization of 5S also helps work proceed more efficiently and consistently.

Furthermore, 5S encourages the involvement of all employees in maintaining and improving work processes, thereby meeting the ISO 9001 requirement for employee participation (Clause 7.3). Finally, 5S lays the foundation for continuous improvement, enabling the company to consistently enhance efficiency and work quality while complying with ISO 9001’s continuous improvement requirements (Clause 10.3).

Integrating 5S and Six Sigma

When combining 5S and Six Sigma, workshops can optimize production processes and improve product quality efficiently. The 5S system creates an organized, tidy workspace that easily identifies problems. This is crucial for implementing Six Sigma, especially in the DMAIC (Define, Measure, Analyze, Improve, Control) process. A standardized and structured work environment helps quickly detect and resolve issues.

Conversely, Six Sigma provides powerful statistical tools to measure and analyze data, thus supporting the improvement of 5S processes. Applying Six Sigma to 5S not only improves efficiency but also reduces variability in production processes, enhancing product quality and lowering production costs.

Combining 5S and TPM (Total Productive Maintenance)

When combining 5S and TPM (Total Productive Maintenance), maintenance activities and the improvement of production quality are optimized effectively. The application of 5S creates a clean and orderly work environment, which is the foundation for successful TPM implementation. A tidy workspace not only makes equipment maintenance easier but also helps detect potential issues early on.

In particular, the “Cleanliness” (Seiso) principle of 5S plays a crucial role in equipment maintenance. It helps minimize incidents, extend equipment lifespan, and supports effective preventive maintenance in TPM.

When combined, 5S and TPM not only ensure long-term effectiveness but also ensure that equipment remains in optimal operating condition, reducing downtime and enhancing product quality, thereby boosting overall factory productivity.

Frequently asked questions

Which industries can apply 5S?

5S can be effectively applied in all sectors, from manufacturing and management to services and trade. In particular, 5S plays a crucial role in improving productivity and work quality.

When 5S is successfully implemented, the factory will have a clean, organized, and safe work environment. This not only enhances work efficiency but also creates a healthy workspace, contributing to the long-term success and sustainable growth of the business.

What solutions help maintain the 5S spirit over time?

To maintain the 5S spirit in the long term within a factory, the implementation of systematic and continuous solutions is essential. First, regular training and communication for employees will help reinforce 5S knowledge, ensuring that everyone understands the objectives and processes clearly.

Additionally, commitment from leadership is a key factor. Leaders need to show direct involvement and encourage employees to maintain 5S in their daily tasks. To strengthen the 5S spirit, reward programs and competitions can be applied, which will motivate employees and foster effort.

Moreover, regular inspections and monitoring will help identify problems promptly and maintain 5S standards. Finally, continuous improvement of work processes is an indispensable factor to ensure that 5S is always optimized and adapted to changes in production operations.

What is the difference between 5S and previous management methods?

The main difference between 5S and traditional management methods lies in their objectives and approaches. While traditional methods focus only on final results, such as increasing productivity and reducing costs, 5S emphasizes building an organized work environment from the beginning. This not only enhances work efficiency but also minimizes risks during production.

The 5S system requires the participation of all employees, from workers to managers, rather than just top-down directives as in older methods. It serves as a company culture foundation, promoting continuous improvement and self-discipline in each individual.

In addition, 5S also focuses on protecting the health and safety of employees, an aspect often overlooked by traditional methods. The clean and safe work environment created by 5S helps reduce workplace accidents and health issues.

Conclusion

In conclusion, the implementation of the 5S system in factory management not only helps optimize work performance but also creates a scientific, safe, and efficient work environment. By maintaining an organized, clean workspace and encouraging continuous improvement, 5S helps minimize waste, optimize production processes, and enhance work quality. By promoting the participation of all employees, from workers to managers, 5S is not just a management method but also a cultural foundation that drives the sustainable development of the factory.